3 Exciting Reasons to Check Out the 3DEXPERIENCE Platform in 2026

If your team is thinking about modernizing how it designs, simulates, and delivers products, the 3DEXPERIENCE platform is worth a close look. Recent customer feedback and Converge positioning consistently points to three practical advantages that make the platform stand out: cloud-native collaboration and a single source of truth, integrated simulation and validation, and built-in AI and modern cloud services that plug into the CAD tools your engineers already use. Let's dive in.

1) Cloud-native collaboration — everyone works from the same, live product data

One of the most powerful benefits customers mention is how the platform removes version chaos and turns the BOM, CAD files, and product data into live information that everyone across engineering, manufacturing, purchasing, and service can access. With data hosted in the cloud, teams can view the latest model, share links for review, and mark up designs without juggling emailed files or fragile network shares. This dramatically simplifies handoffs and keeps everybody aligned on the current design state — which reduces rework and speeds decisions during product development. The platform’s collaboration capabilities are a central part of its value proposition and are repeatedly highlighted as a reason organizations move to 3DEXPERIENCE.

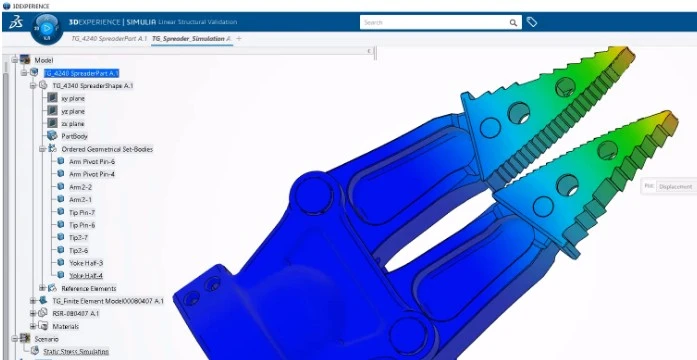

2) Integrated simulation and validation — test earlier, iterate less

Customers also respond strongly to the platform’s integrated simulation tools. Because simulation (FEA, multi-physics, etc.) lives on the same platform as CAD and product data, teams can run validation earlier in the design process, share results instantly, and reduce the number of physical prototypes and associated costs. The platform’s simulation ecosystem (powered by market-leading engines) is presented as a straightforward way to improve product quality while shortening development cycles — a capability that resonates with engineering teams who want proof of performance without lengthy toolchain handoffs.

Customers also respond strongly to the platform’s integrated simulation tools. Because simulation (FEA, multi-physics, etc.) lives on the same platform as CAD and product data, teams can run validation earlier in the design process, share results instantly, and reduce the number of physical prototypes and associated costs. The platform’s simulation ecosystem (powered by market-leading engines) is presented as a straightforward way to improve product quality while shortening development cycles — a capability that resonates with engineering teams who want proof of performance without lengthy toolchain handoffs.

3) Built-in AI and modern cloud services that fit your existing CAD workflows

Another area of recent praise is the platform’s forward-looking AI and cloud-first approach. Dassault’s private AI assistant (AURA) and platform-level cloud services provide contextual search, summarization, and in-platform assistance that help engineers find knowledge faster and automate routine tasks — all while respecting access rights so your IP stays secure. At the same time, the platform doesn’t force a rip-and-replace of current tools: it supports browser-based access and solutions such as SOLIDWORKS Desktop-as-a-Service, enabling engineers to keep working in familiar CAD environments while benefiting from cloud data management and platform intelligence. This combination — AI assistance plus managed cloud delivery and easy CAD integration — is exactly what customers tell us helps them increase productivity with minimal disruption.

What that means for your team

Put together, these three advantages let teams design faster, validate earlier, and get product data flowing reliably to the people and systems that manufacture and support the product. For organizations facing complex data, distributed teams, or heavier demands for traceability and faster iteration, the 3DEXPERIENCE platform becomes a pragmatic way to modernize workflows without throwing out the tools that already work for engineers.

Want to see it in your environment?

If you’d like, Converge can arrange a short demo that focuses on the use cases that matter most to you — collaboration for distributed teams, a simulation proof-of-value project, or an AI-driven productivity demo. We’ll tailor the session to show how the platform can connect to your current CAD workflows and the concrete ROI you can expect.