Titan Steel Door - From Chaos to Confidence: A Manufacturer’s Journey

Every design/manufacturing company's story is unique, but at the core you will find very common issues that we at Converge have found creative and repeatable solutions to. Titan Steel Door is just one company, but their previous pain points around CAD data are truly universal.

The Setup...

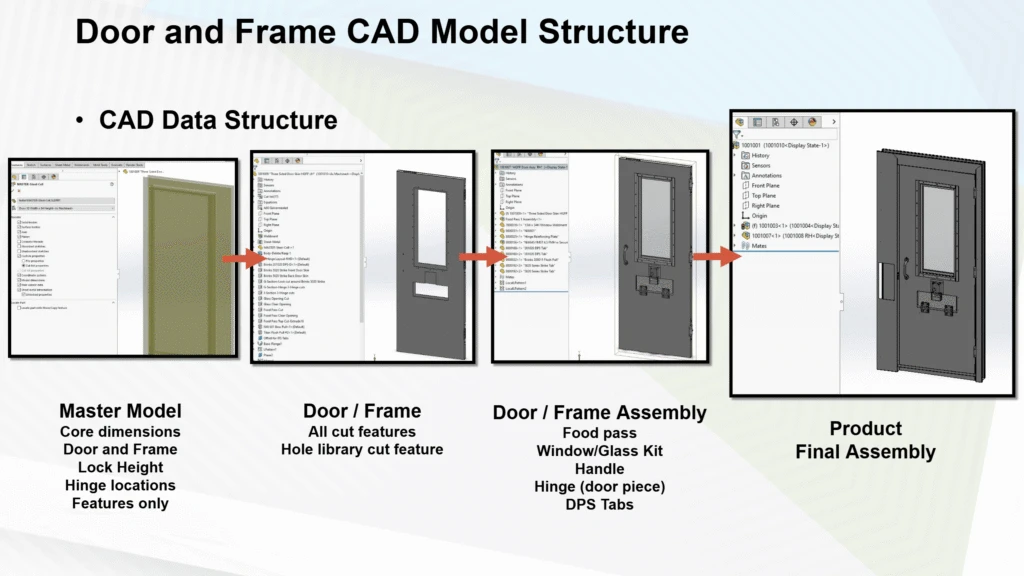

When the Converge team sat down for a casual breakfast meeting with Titan Steel Door in Murrayville, Georgia, we quickly discovered the stakes were high. Titan was preparing for a major growth phase—but they were stuck. Costly errors were happening on the shop floor. Doors and frames, the core of their product offering, didn’t fit together. The culprit? Design mismatches stemming from an inefficient and outdated CAD workflow, made worse by a complete lack of Product Data Management (PDM).

What We Found...

At the time, Titan’s engineering process relied heavily on copying and modifying existing files. Every variation of a product resulted in a new file set—dozens of duplicate designs with no control, no standardization, and no opportunity for reuse. Without an internal CAD administrator or dedicated IT support, the team was overwhelmed.

Opportunities For Improvement At All 3 Pillars...

It seemed like there were opportunities to improve CAD workflows at every stage: Data Creation, Data Management, and Data Distribution. Stay tuned to learn how Titan Steel door solved those issues hand-in-hand with Converge as we dissect a specific challenge their design team was facing over the next months. This blog series will discuss the common issues we found, and the solutions we put in place to solve those universal issues.

Read on to learn how we solved Titan Steel Door's CAD Data Creation problems by resetting their CAD workflows, and be sure to catch our monthly webinar series that focuses on each of the 3 Pillars of CAD Data.

Part 2 - Improving CAD Data Creation

Part 3 - Improving CAD Data Management

Part 4 - Next-Level Distribution: Drawings on Display

Part 5 - Coming in November